Over the past year, the aluminium industry has faced various challenges due to the limited availability of raw materials. In aluminium production, there has been a great increase in the use of magnesium as an alloying element. Magnesium is a critical metal, and 90 percent of the world’s magnesium production is controlled by China.

“Already in the spring, there were some indications that it could become more difficult to obtain magnesium, as China was planning to close its magnesium plants and reduce its magnesium production by half. So far the industry has managed by using magnesium stocked in Europe, but now the stocks have been exhausted and the supply of magnesium is almost entirely dependent on China,” says Mäkelä Alu’s Purchasing Director Ari Kytölä.

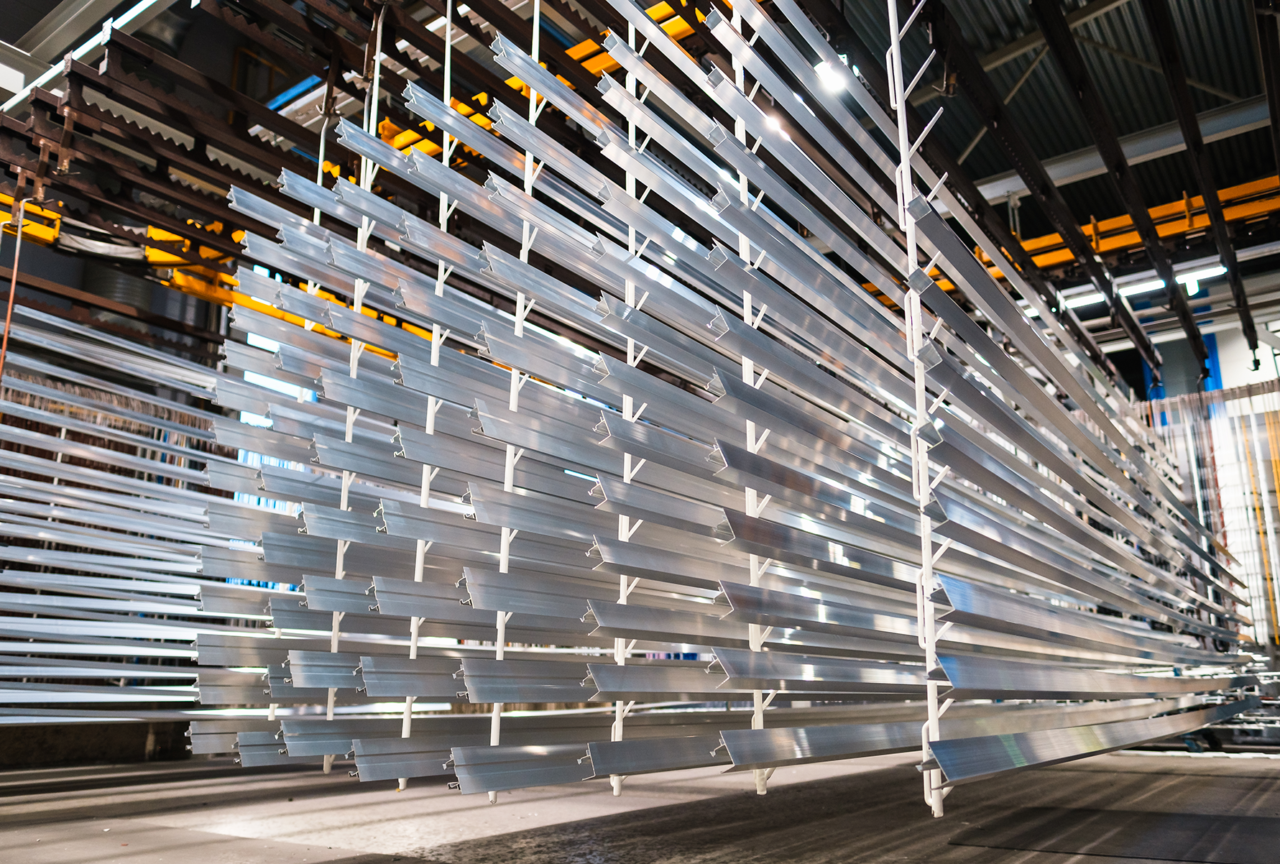

The proportion of magnesium in aluminium profiles is 0.5–1%.

Mäkelä Alu counts on its raw material suppliers

Mäkelä Alu has been in regular contact with its raw material suppliers and is constantly monitoring the market situation.

“Our suppliers have confirmed the availability of magnesium for the first quarter of 2022. They are currently negotiating second-quarter deliveries. We will inform our customers as soon as we know more,” says Kytölä.

Kytölä stresses that while the situation is still uncertain, it does not mean that there will be no magnesium available at all. At some point, however, its availability may be more limited than before.

“I have strong confidence in our partners and their market position, despite increased competition. Our three Nordic raw material suppliers are the best in the industry. We know that they successfully manage their supplier relationships and contracts.”

Magnesium is also used in Mäkelä Alu’s foundry, where scrap metal is melted into recyclable billets. The supply of magnesium at the foundry has been secured until mid-2023.

Mäkelä Alu’s annual agreements ensure the availability of aluminium

In addition to strong partnerships, Mäkelä Alu ensures the availability of its raw materials through annual purchase agreements.

There are basically two ways to purchase raw materials: through annual purchase agreements or through spot trading.

“Our raw material procurement is based on annual agreements. In this way, we have been able to secure the delivery of our raw materials, and we have always received the materials as agreed. We can always count on our partners,” says Kytölä.

Annual agreements have recently proven their true value as the spot market has been cleared as a result of increased use of aluminium. Those who have relied on the spot market are now in a difficult situation.

The paint market has stabilised

During this year, Mäkelä Alu, like other companies, has had to tackle various challenges due to the limited availability of paint.

“The situation with paint is now more stable, and we have no longer experienced any significant problems with availability. We have experienced some delays in the delivery of certain individual colours, but these types of delays are perfectly normal. Overall, the situation is relatively good,” says Kytölä.

In this case, too, Mäkelä Alu has benefited from reliable long-term partnerships where challenges can be solved together.

Mäkelä Alu will continue to monitor this situation as well.