Mäkelä Alu’s responsibility is reflected in raw material procurement

16/12/2021

As part of efforts to meet climate and environmental sustainability goals, society is shifting away from fossil fuels towards clean energy sources. Aluminium plays an important role in this transition, as it is extensively used, especially in electricity-based energy systems.

The International Energy Agency (IEA) estimates that the use of aluminium in the power sector will double by 2040.

The use of aluminium is also increasing in the transport sector. Due to its light weight, aluminium is used in electric car batteries, car profiles, buses, trains, boats, and airplanes.

The use of aluminium supports the transition to a carbon-neutral society, which is why in 2020, the European Commission added bauxite, the main raw material in aluminium production, to its list of critical raw materials.

Finnwatch investigated the origin of aluminium used in Finland

In October 2021, Finnwatch published an extensive report on aluminium imports to Finland. The report mainly examined aluminium production in Brazil and its impact on the environment and local communities in the state of Pará. In connection with the report, Finnish companies were asked about their responsibility requirements and controls.

A survey was sent to 23 Finnish companies that use aluminium in their operations. Many did not reply, and some companies did not know the origin of the aluminium they used.

One of the respondents was Mäkelä Alu, who responded to the survey openly and reported that about 25–30 percent of its aluminium comes from Brazil.

Aluminium production involves various steps

In the aluminium production process, bauxite ore is first mined from the soil and aluminium oxide is separated from it. Bauxite deposits are mainly found in the equatorial regions.

Aluminium oxide can be separated from bauxite in two different ways: by the Bayer or Pedersen process.

The Bayer process is the most common process used to refine bauxite into alumina. The process produces alkaline red mud (bauxite residue), which is waste composed of titanium, iron, and aluminium oxides, among other things. Production facilities may collect the mud in large basins without neutralising it, or wash the mud with water to neutralise the acids. After washing, the remaining solid material can be stored.

In the Pedersen process, iron is separated into a separate product from the mud, leaving soil that contains calcium and silica in the process. This soil can be used, for example, in the construction industry. This method does not generate red mud, but it requires significantly more energy.

Finally, pure aluminium is obtained from aluminium oxide through electrolysis.

Mäkelä Alu’s raw materials come from reliable suppliers

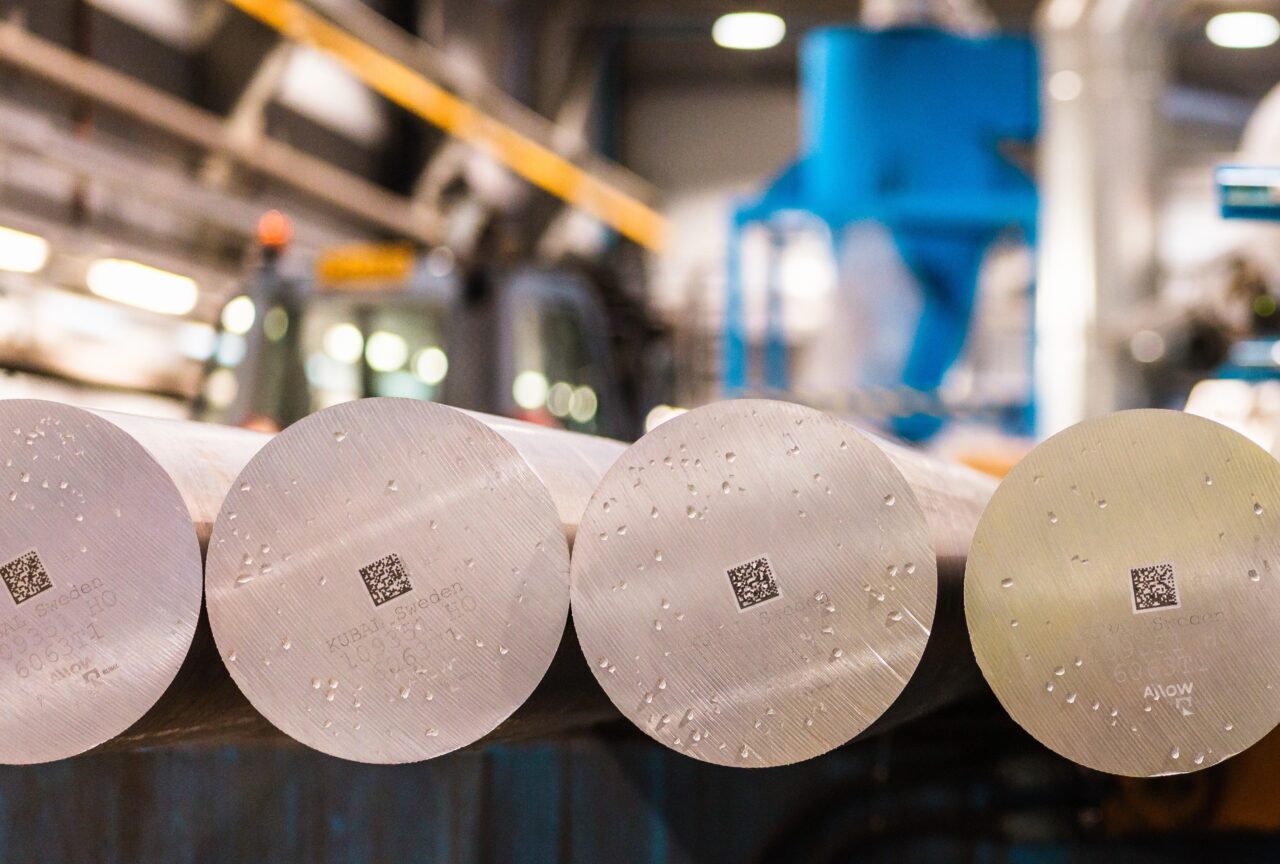

Before the aluminium arrives at Mäkelä Alu’s warehouse, it goes through various processes and travels from the equator to the Nordic countries.

Mäkelä Alu procures its aluminium from three Nordic suppliers. Mäkelä Alu has established long-term partnerships with these companies and the raw material suppliers were carefully selected, especially with environmental sustainability in mind. In terms of CO2 emissions, the suppliers are among the best in the world when it comes to producing low emissions throughout the production chain.

“Our experience and perceptions of our suppliers’ occupational safety, responsibility, and environmental sustainability practices have been very positive. Based on the information we have received, we are convinced that our raw material suppliers operate responsibly and aim to minimise their environmental impact in all their operations,” says Purchasing Director Ari Kytölä.

Mäkelä Alu monitors the responsibility of its suppliers

Mäkelä Alu employs a variety of strategies to ensure the responsible operation of its suppliers.

“This work is part of our efforts to build the best and most responsible aluminium production chain in the world, whether in terms of achieving our own carbon neutrality goal for 2025 or ensuring the responsible operations of our raw material suppliers in terms of environmental and social impact,” says Mäkelä Alu’s EHSQ Manager Päivi Venesoja.

The raw material suppliers’ environmental sustainability and responsibility practices are reviewed in connection with supplier audits. Responsibility issues, such as the procurement of minerals from areas of conflict, are also constantly discussed with the suppliers.

Mäkelä Alu will continue to develop its operations responsibly

Aluminium will be a key material in the future, but its responsible production may be challenging at the beginning of the process. Mäkelä Alu contributes to the transition to a more energy-efficient and green future by acting responsibly and minimising its environmental impact.

“The report that was recently completed will help us in this work, and we are constantly developing our operations,” says Venesoja.

In the future, the implementation and monitoring of reforestation activities will be further examined in connection with supplier audits. In addition, the suppliers will be asked to provide a more detailed analysis of the origin of their raw materials.